In the bustling landscape of Thai industries, the utilisation of chemicals is ubiquitous, spanning various sectors from manufacturing to agriculture. As an experienced Health, Safety, and Environment (HSE) Consultant with a specialisation in occupational safety and health across Asia, Africa and the Middle East, I’ve witnessed first-hand the critical importance of chemical safety in Thailand ensuring the well-being of workers and the sustainability of businesses. This guide aims to provide a comprehensive overview of chemical safety practices tailored specifically to the context of Thai industries.

Understanding Chemical Hazards

Chemicals, while indispensable in modern industrial processes, pose inherent risks to human health and the environment. Understanding these hazards is paramount to effectively managing them. Chemicals can be classified based on their properties and potential risks, ranging from corrosivity and toxicity to flammability and reactivity. In regards to chemical safety in Thailand, common chemical hazards include solvents, acids, pesticides, and industrial cleaning agents.

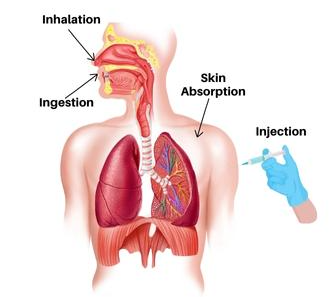

Routes of Exposure and Potential Health Effects

Chemical exposure can occur through various routes, including inhalation, ingestion, and dermal contact. Each route presents its own set of risks, with potential health effects ranging from acute toxicity and respiratory irritation to long-term health consequences such as cancer and reproductive disorders. Personal anecdotes from my career emphasise the importance of vigilance in identifying and mitigating exposure risks. I recall an incident where improper handling of a corrosive chemical resulted in severe burns to a worker’s skin, highlighting the need for robust safety protocols.

Regulatory Framework in Thailand

Thailand has established a comprehensive regulatory framework to govern chemical safety in industries. The Hazardous Substances Act and the Factory Act are primary legislations that outline obligations for chemical manufacturers, importers, and users. Additionally, regulatory agencies such as the Department of Industrial Works (DIW) and the Ministry of Industry play pivotal roles in enforcing compliance and promoting best practices.

Roles and Responsibilities

Navigating the regulatory landscape can be daunting, but it’s essential for all stakeholders to understand their roles and responsibilities. As an HSE Consultant, part of my responsibility involves advisory to ensure that client operations align with regulatory requirements and industry standards. This may entail conducting gap-analysis to determine the risk factors, designing audit & inspection programs, developing record systems, and advising on how to engage with regulatory authorities to address any compliance concerns.

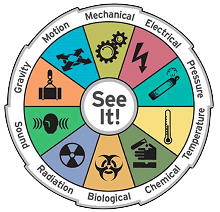

Risk Assessment and Management

Effective risk assessment is the cornerstone of chemical safety management. By systematically identifying hazards, evaluating risks, and implementing control measures, organisations can minimise the likelihood of incidents and safeguard the health of workers. My experience has taught me the value of conducting comprehensive risk assessments tailored to the specific characteristics of our operations. This includes considering factors such as the toxicity of chemicals, the frequency of exposure, and the adequacy of existing control measures.

Emergency Response Planning

Despite our best efforts to prevent incidents, emergencies can still occur. That’s why it’s imperative to have robust emergency response plans in place. These plans should outline procedures for containing spills, cleanup and disposal, evacuating personnel, and coordinating with external response agencies. Regular drills and simulations help ensure that employees are prepared to respond effectively in the event of an emergency. I vividly remember a simulated chemical spill exercise where our team demonstrated exceptional coordination and response capabilities, underscoring the importance of preparedness. If you do have hazardous chemicals on site, be sure to consider HAZMAT training, which includes methodologies to safely clean off wet chemicals from people that have been exposed. Too often this step isn’t undertaken and this can cause further exposure to the medical response and hospital teams.

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) serves as a last line of defence against chemical hazards. Selecting the appropriate PPE and ensuring its proper use are critical aspects of chemical safety management. This involves providing workers with adequate training on PPE selection, usage, and maintenance. Reflecting on my experiences, I’ve seen first-hand the difference that proper PPE can make in preventing injuries and illnesses. From respirators to chemical-resistant gloves, equipping workers with the right gear can significantly reduce their risk of exposure. I have also witnessed many instances where workers were using inadequate protection as well. Always read the SDS (Safety Data Sheets) for advice on the right PPE but keep in mind that not all SDS’s include adequate descriptions of the PPE (i.e. “Wear rubber gloves”. What kind?).

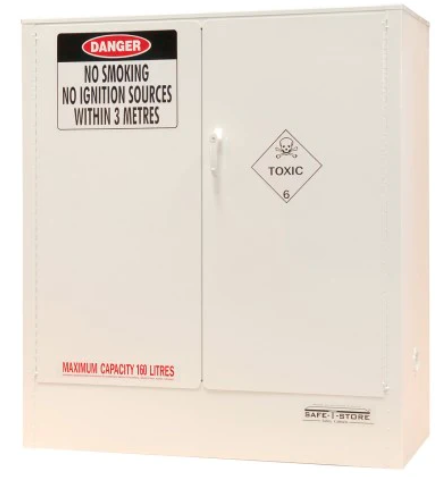

Safe Handling and Storage Practices

Proper handling and storage of chemicals are fundamental principles of chemical safety. This includes adhering to guidelines for labelling, segregation, and compatibility to prevent accidents and contamination. Implementing measures such as secondary containment systems and ventilation controls further mitigate risks. In my role, I’ve overseen the design and implementation of state-of-the-art storage facilities equipped with advanced safety features to minimise risks associated with chemical handling and storage.

Storage Compatibility and Segregation

One aspect that warrants particular attention is the compatibility of chemicals during storage. Mixing incompatible chemicals can result in hazardous reactions, potentially leading to fires, explosions, or toxic releases. Segregating chemicals based on their properties and hazards helps minimize the likelihood of accidental mixing. Implementing colour-coded labelling systems and providing clear signage further enhances safety by facilitating easy identification of stored chemicals.

Chemical Exposure Monitoring

Monitoring and measuring chemical exposure levels are essential components of a proactive safety program. This involves utilizing monitoring equipment such as air samplers and personal dosimeters to assess exposure levels in the workplace. Regular monitoring not only ensures compliance with exposure limits but also provides valuable data for assessing the effectiveness of control measures. Through continuous monitoring efforts, organisations can identify emerging trends and proactively address potential risks before they escalate. Keep in mind that the law states that employees exposed to chemical hazards as part of their daily work, must have annual checkups. However, check-ups are often seen as a routine “employee welfare” perk and aren’t always analysed against a benchmark. You are looking for potential occupational exposure and illness trends in your employees. In my past roles, I developed comprehensive analysis of health records compared to known chemical exposure illnesses. This analysis helped us to discover gaps in the chemical handling procedures and correct them.

Training and Education

Comprehensive training and education are key pillars of a strong safety culture. By equipping employees with the knowledge and skills they need to identify hazards and work safely, organisations can foster a culture of accountability and responsibility. Training programs should cover a range of topics, including chemical hazards, use of Safety Data Sheets, safe handling procedures, emergency response protocols (i.e. HAZMAT), and the proper use of PPE.

Emergency Preparedness and Response

No matter how diligent we are in our efforts to prevent incidents, emergencies can still occur. That’s why it’s crucial to have robust emergency preparedness and response plans in place. These plans should outline clear procedures for responding to chemical spills, fires, and other emergencies. Regular drills and exercises help ensure that employees are familiar with their roles and responsibilities and can respond effectively under pressure. Reflecting on past incidents, I’ve seen firsthand the difference that a well-prepared and coordinated response can make in mitigating the impact of emergencies.

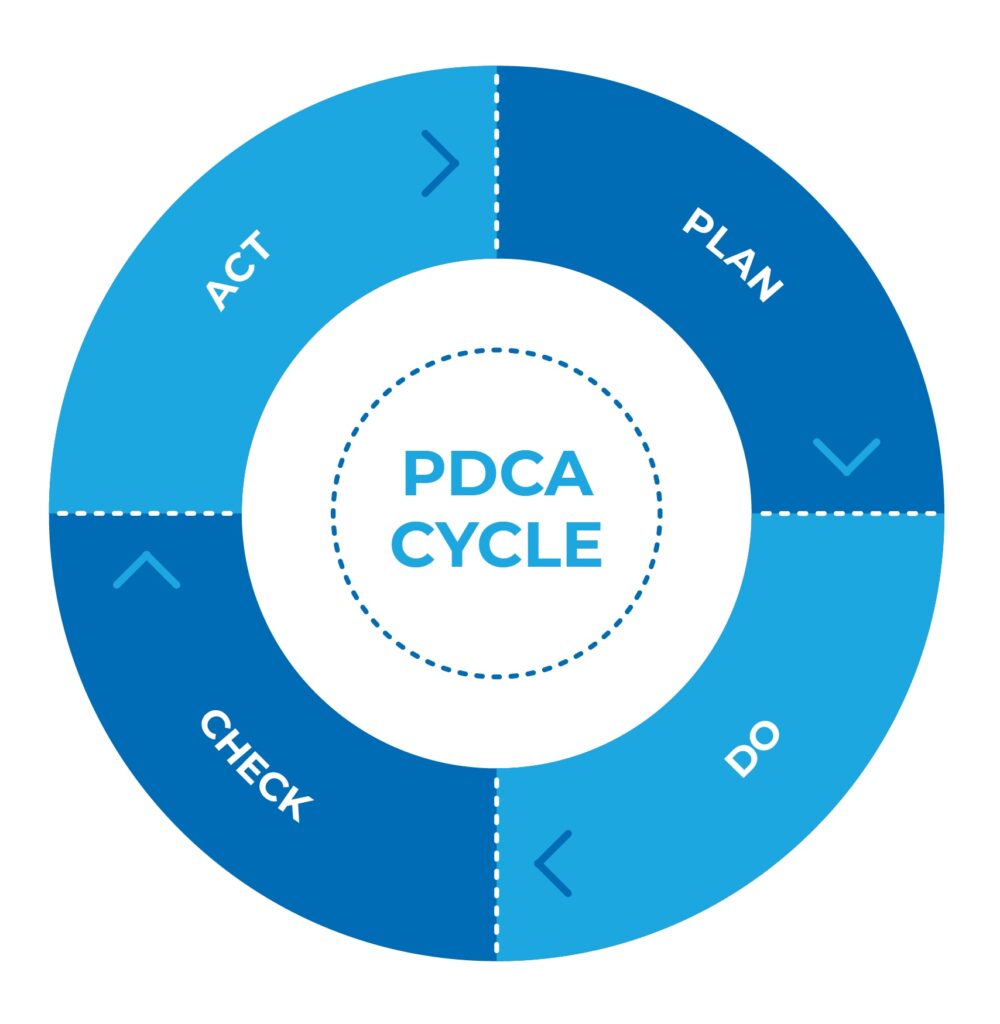

Continuous Improvement and Compliance

Achieving and maintaining chemical safety in Thailand, requires a commitment to continuous improvement and compliance. This involves regularly reviewing and updating safety procedures, conducting audits and inspections, and staying abreast of regulatory changes. By embracing a culture of continuous improvement, organisations can identify opportunities to enhance safety performance and mitigate emerging risks. As an HSE Manager, I’ve worked closely with cross-functional teams to implement process improvements and ensure ongoing compliance with regulatory requirements.

Conclusion

In conclusion, chemical safety in Thailand is a multifaceted endeavour that requires collaboration, vigilance, and commitment from all stakeholders. By understanding the hazards associated with chemicals, complying with regulatory requirements, and implementing robust safety measures, Thai industries can create safer and healthier workplaces for their employees. As an HSE Consultant, I remain dedicated to promoting a culture of safety and driving continuous improvement in chemical safety practices.